Manufacturing on Demand

Certified and Quality Driven

ITAR Registered

ISO 9001:2015,ISO 13485:2016 and AS9100D Certified

Parts in as fast as 1 day

3D Printing

Sheet Metal

Waterjet Cutting

lnjection Molding

CNC Machining

Urethane Casting

Laser Cutting

Buy Material

ABOUT US

FindTop | A one-stop manufacturing sourcing platform that seamlessly connects buyers and manufacturers with a network of more than 10,000 qualified manufacturers, offering a wide range of materials and processes to provide a comprehensive solution for your custom parts project, with new users receiving a $500 coupon for your first registration.

Our manufacturing capabilities

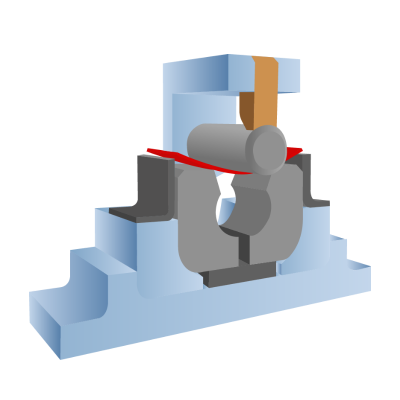

CNC machining service

FINDTOP has more than 1,000 processing machines in the field of machining, a wide range of metal and plastic materials, and a wide range of surface treatment capabilities.

Molding service

FINDTOP offers highly customized precision molding, on-demand molding and mass production molding services.

Manufacturing services

FINTTOP offers customers fast and cost-effective production, including a wide range of custom sheet metal and assembly options.

Stamping service

FINDTOP offers precision machined composite stamping parts and components.

Casting service

Using advanced casting methods, FINDTOP focuses on the economical manufacture of small, complex parts with specific color, durability and strength requirements.

Forging service

At Findtop, we use advanced forging technology to produce metal parts with exceptional strength and durability.

Are you ready to obtain quotes?

Industrial precision manufacturing applications

Automotive

In the highly customized automotive industry environment, FINDTOP is committed to helping customers and partners build automated intelligent production systems and provide personalized solutions and services. With extensive expertise in industrial internet of things, big data analytics, and intelligent manufacturing, FINDTOP enables automakers to achieve mass customization and flexible manufacturing.

Consumer products

At FINDTOP, we partner with leading consumer goods brands to accelerate innovation and bring products to market faster. Our advanced manufacturing technologies support rapid prototyping, flexible production and resilient supply chains. With our industrial 3D printers, customers can iterate on prototypes in days instead of weeks.

Energy

At FINDTOP, we are committed to driving innovation and supporting the transition to renewable energy and sustainability. Our customized manufacturing solutions empower companies across the energy sector to bring novel designs and technologies to market faster.

For new energy vehicle manufacturers, we offer lightweight prototyping and production using advanced materials like composites and alloys. This allows creating high-strength, energy-absorbing structures to improve safety and extend range.

Industrial

FINDTOP’s engineering team provides rapid prototyping of new mechanical components to test iterative upgrades of equipment and machinery. By 3D printing or CNC machining custom components, industrial companies can verify the performance of next-generation designs.

Our capabilities cover mold design, CNC production tools, injection molding and other scalable processes to manufacture upgraded components. We ensure quality control through inspection, testing and surface treatment.

Lighting

At FINDTOP, we leverage expertise across metal processing technologies to produce high-quality lighting components for our clients. For metal lighting parts like heat sinks, reflectors and housings, we utilize progressive stamping to generate complex geometries from steel, aluminum and other alloys. Our automated presses and years of tooling experience enable both rapid prototyping and volume production of precision metal components.

We expertly design and machine molds, and can accommodate high performance resins like PMMA, PC and ABS to meet optical clarity and durability requirements.

Medical And Dental

At Findtop, we understand the unique needs of the healthcare industry for high-mix, low-volume production. Our precision CNC machining capabilities allow us to quickly prototype custom components for medical devices based on 3D CAD models. We can accommodate small to medium batch sizes with fast turnaround times. For disposable medical consumables such as syringes, sample collection kits and IV assemblies, we offer plastic injection molding. We specialize in the design and manufacture of high tolerance molds and fixtures to ensure consistent quality output.

Robotics

At Findtop, we have the expertise to provide custom components and solutions for robotics and automation systems to enable smart manufacturing and digital transformation. Findtop offers rapid prototyping, small series production, and continuous improvement of robotics and automation hardware. We help manufacturers implement flexible solutions to adapt to changing needs.

Electronics And Semiconductors

Excellence in electronics and appliance manufacturing, FINDTOP has been providing quality custom manufacturing services to leading electronics, appliance and semiconductor companies. Our expertise covers the entire product life cycle. Whether you need rapid prototyping of new concepts, support to turn designs into mass production, or need to completely outsource manufacturing, FINDTOP has the capabilities. FINDTOP’s global supply chain offers cost-competitive production in any quantity, from low-hybrid prototypes to high-hybrid end products. We help you get to market faster, making high quality electronics and appliances to your exact specifications.

BORN FOR NON-STANDARD MANUFACTURING

Accurate delivery date

We own a huge network of over 10,000 factory collaborators proficient in 3D printing, sheet metal forming, machining, injection mold making and other skills, which enables them to provide purchasers with prompt and high-quality non-standard parts production and processing services.

Excellent service

Our AI smart offer system provides quick and correct offer facilities. The innovative collective production system offers digital depiction facilities for manufacturing methods. The above 100 customer support team delivers extensive pre-sale as well as post-sale professional services.

High quality

We have over 200 standardized processing techniques, more than 100 diverse testing devices, as well as a quality examination team of over 100 people. All complete products are put through rigorous quality checks prior to dispatch in order to assure 100% quality verification of delivered products.

Why Choose FINDTOP?

FINDTOP is an industry 4.0 enabled manufacturing platform, connecting customers directly to production capacity. By leveraging a network of highly qualified engineers and optimized supply chains, we help bring designs to life efficiently through smart factories.

- Instant quote

- Expert DFM feedback reduces risk and costs

- The most competitive prices

- On-time delivery guarantee

- Complete production transparency

- Quality assurance

- Security platform and expert panel support

- Reduce risk with our reliable manufacturing services

From Our Clients

Anya Siennadia

Brayden Charles

Barak Stuart

John Doe

Our Stats

Although we are still small, but we are very focused, that’s whey we will spend more energy to serve each of our customers.

PROJECT DONE

SATISFIED CLIENTS

Suppliers

Parts deliver

Trusted By Top Companies In The World

We have connected thousands of manufacturing cooperative enterprises to realize the organic connection of the whole industrial chain!

Our goal is to make it easy for each customer to access and use high-quality resources in all aspects of the global manufacturing industry.

Are you ready to obtain quotes?

Material guide

Finding the right materials is crucial to designing and manufacturing parts that meet your exact needs. The FINDTOP Materials Guide provides you with comprehensive information on a wide range of materials available for your project, enabling you to make informed choices.

Surface treatment service

Surface treatment service

To take your product’s surface performance to the next level, FINDTOP Surface Treatment Center offers common and advanced coating processes including anodizing, electroplating, powder coating, physical vapor deposition and more. We use automated equipment and strict process control to ensure uniform coating of each part.

Rapid prototyping service

Rapid prototyping service

Rapid prototyping utilizes fast digital manufacturing processes like 3D printing, CNC machining, and injection molding to quickly iterate design concepts. By producing affordable prototypes in 1-3 days for $5-50 each, engineers can gather key insights through hands-on testing early in the design cycle, before finalizing tooling.