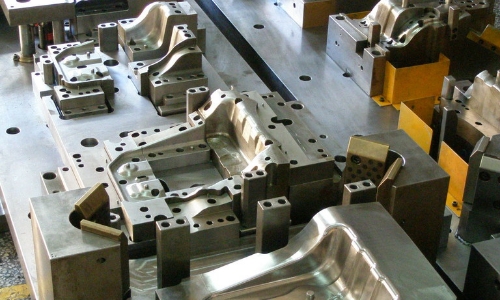

Metal stamping

Metal stamping is a method of placing metal plates between molds and using the high-speed impact force of the punching machine to press them out of a predetermined shape. It belongs to metal processing technology, has the advantages of high production efficiency, high precision products, mainly used in the production of various hardware products and tools.

The main advantages of metal stamping are:

1. High production efficiency. Automatic production, fast production speed, large capacity.

2. High precision of the product. Affected by the mold accuracy, the product accuracy is higher, the dimensional accuracy is within 0.01mm.

3. Wide range of applications. Can produce all kinds of hardware accessories, tools and instruments, etc., a wide range of applications.

4. High metal utilization rate. Can reach more than 90%, the loss is small.

Findtop's strengths in metal stamping

We are working closely with leading suppliers of metal stamping technology to supply high quality and low cost custom machinated parts from Asia using our own developed technology. The whole procurement process is completely transparent, you can keep track of the latest order through our order tracking system.