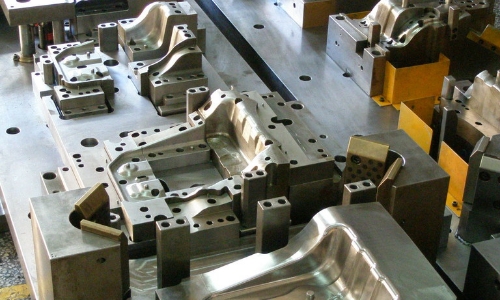

Progressive die stamping

Progressive die stamping is an important method in die forming process. It is based on the ordinary die punching process, using different depth of stamping steps, so that hollow or thin wall workpiece in the process of die punching forming gradually form the required shape of the process. Progressive die stamping is mainly used to produce high strength, thin wall or large size hollow parts.

The main advantages of progressive die stamping are:

1. Suitable for high strength and large size hollow parts. It can produce large hollow parts requiring high strength and precision.

2. Good forming quality. Multi-stage forming, gradually form the required shape, adjacent two stages of deformation is small, reduce wrinkle and tear and other defects.

3. High metal utilization rate. Progressive forming, small material dressing allowance, less metal loss, higher metal utilization rate.

4. High production efficiency. General use of automatic production, continuous action, high production efficiency.

5. The equipment and mold are complicated. Need to use multistage feed system and complex multistage mold, equipment and mold cost is high.

Findtop's strengths in progressive die stamping

We have established strategic cooperation with leading suppliers in the field of progressive die stamping technology, and use self-developed technology to customize high standard, low price machining parts from Asia. The whole purchasing process is open and transparent, and you can grasp the latest information of orders in real time through our order tracking system.