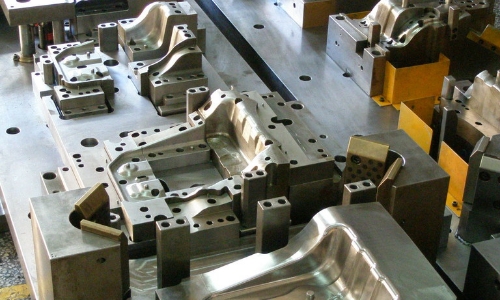

Deep drawing

Deep drawing process is a forming method in which the workpiece is placed in the mold and the mold shape and deep drawing action are used to make the workpiece obtain the three-dimensional shape. It belongs to forging forming technology, which can obtain the forming products with good organization and mechanical properties. It is mainly used for the production of metal parts requiring high strength and high precision.

The main advantages of deep pumping are:

1. Obtain forming products with excellent structure and properties. Deep pumping can obtain fine crystal structure and anisotropy, high strength, high plasticity and high fatigue strength and other good mechanical properties.

2. High dimensional precision. The deep drawing process is controlled by the mold, and the dimensional accuracy of the product is high, which can reach the IT7-IT8 level.

3. High metal utilization rate. Deep pumping process has low metal loss and metal utilization rate can reach more than 90%.

4. High production efficiency. Deep pumping process using automatic equipment, production speed, high efficiency.

5. The equipment and mold are complicated. Need deep drawing equipment and complex mold, equipment investment and mold cost is high.

Findtop's advantage in deep drawing

We are now working closely with top suppliers in the field of deep stretch forming technology to supply high standard, low cost custom machinated parts from Asia using self-developed technology. The whole procurement process is completely open and transparent, and you can follow the latest progress of orders in real time through our order tracking system.