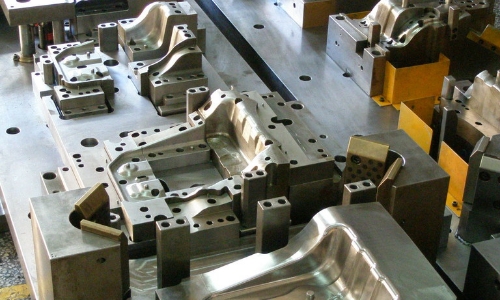

Fine blanking process

Fine blanking process is an advanced form of die blanking technology. It is a forming method to obtain high precision parts by using high precision die and strict process control on the basis of ordinary die blanking process. Precision blanking process can obtain parts with dimensional accuracy up to IT7-IT8, which is mainly used to produce parts with high precision requirements.

The main characteristics of fine blanking process are:

1. High product precision. Using high precision mold and strict process control, the product accuracy can reach IT7-IT8 level.

2. Good surface quality. Precision mold and precision control, product surface quality is good, no obvious defects.

3. High forming efficiency. General use of automatic production, production speed, high efficiency.

4. The equipment and mold should be precise. Need high precision stamping equipment and high precision mold, equipment and mold cost is high.

5. High metal utilization rate. High precision machining, minimized materials, high metal utilization rate, low material loss.

Findtop's strength in precision stamping

We are now working closely with leading suppliers in the field of fine stamping technology, and using self-developed technology to customize high standard and low price machining parts for the Asian market. The whole purchasing process is completely open and transparent, and you can get the latest order information in real time through our order tracking system.