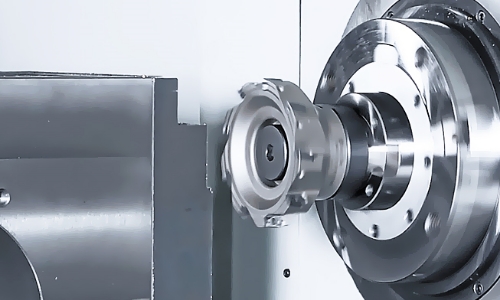

Customized online CNC machining services

- 1 minute quotation, 1 hour online

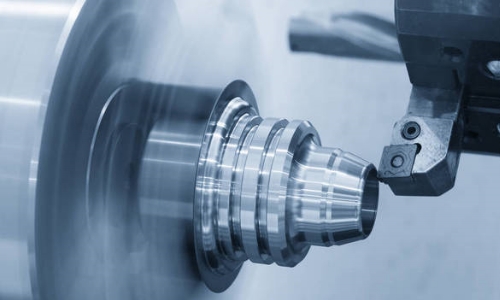

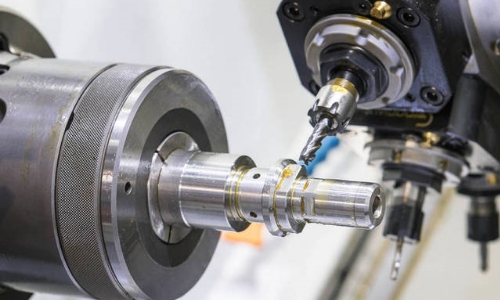

- Milling (3-axis, 4-axis, 5-axis), turning (numerical turning, turning milling composite)

- Supports 20+surface treatment methods

- Multiple business centers worldwide

All uploads are secure and confidential

Our CNC Machining Services

Findtop is responsible for the cutting-edge skills and strong manufacturing talent in the field of mechanical processing. Our quality certification includes ISO 9001, AS 9100, ISO 13485, and ISO 16949. We have over 1000 types of processing machinery, a wide variety of metal and plastic materials, and diverse surface treatment capabilities. Today, Findtop is used in industries including medical, automotive, consumer goods, aerospace, energy, and robotics technology.

the processing energy of findtop

| Attribute | Description |

| Maximum part size |

|

| Tolerance |

|

| Threads and threaded holes | Findtop can adapt to any standard thread size, and we can also process customized threads. |

| Minimum feature size | Usually 0.50 mm (0.02 inch), depending on the geometry of the product and the materials used |

| Burr and chamfer | Deburring by default, chamfering according to specific needs |

| Surface Finish | The standard finish is 32 Ra or better, when getting a quote, you can specify other finishing options |

| Materials |

|

| Delivery Time |

|

| Quality Certifications |

|

*The table above introduces general machining capabilities

machining surface finishes

Alodine

Chromate conversion coating, more commonly known by its brand name Alodine, is a chemical coating that passivate and protects

aluminum from corrosion. It is also used as a base layer before priming and painting parts.

Anodizing

Anodizing is an electrolytic passivation process that grows the natural oxide layer on aluminum parts for protection from wear and

corrosion, as well as for cosmetic effects.

Black Oxide

Black oxide is a conversion coating similar to Alodine that is used for steel and stainless steel. It is used mainly for appearance and for

mild corrosion resistance.

Electropolishing

Electropolishing is an electrochemical process used to improve the surface finish of a part by removing material to level microscopic

peaks and valleys.

Electroless Nickel Plating

Electroless nickel plating (ENP) is a reaction that deposits a nickel-phosphorus alloy onto the surface of a metal. Compared to

electroplating, it has more uniform thickness and superior wear and corrosion resistance.

Media Blasting

Media blasting uses a pressurized jet of abrasive media to apply a matte, uniform finish to the surface of parts.

Nickel Plating

Nickel plating is a process used to electroplate a thin layer of nickel onto a metal part. This plating can be used for corrosion and wear

resistance, as well as for decorative purposes.

Passivation

Passivation is a chemical reaction that causes a material to be less affected by corrosion or other environmental factors.

Powder Coating

Powder coating is a process in which a dry powder paint is applied to a metal surface. Unlike traditional, liquid paint, powder coating does not need a solvent to keep the binder and filler of the paint in liquid suspension.

Tumbling

Tumbling is a finishing process that is used to clean, deburr, and slightly smooth smaller part.

Zinc Plating

Zinc plating, which is also known as galvanization, is applied to prevent the surface from oxidizing or corroding.

*Zinc plating, which is also known as galvanization, is applied to prevent the surface from oxidizing or corroding.

applications of CNC machining

Fast Tooling

As CNC is compatible with nearly any material, it is perfectly suited for expeditious manufacturing of tooling such as jigs or casts.

Fast Prototyping

CNC is remarkably fit for prototypes made of manifold materials, diminutive value per element, and expeditious creation.

End-use Parts

CNC is remarkably fit for prototypes made of manifold materials, diminutive value per element, and expeditious creation.

why choose findtop for cnc machining?

Multiple Choice

A wide range of combinations of materials, tolerances, surface treatments, and markings.

On Demand Manufacturing

Place orders directly with our team, with the help of our internal engineers and flexible delivery times.

Real Time Orders

Stay up-to-date with the latest orders in real-time through our order management system.