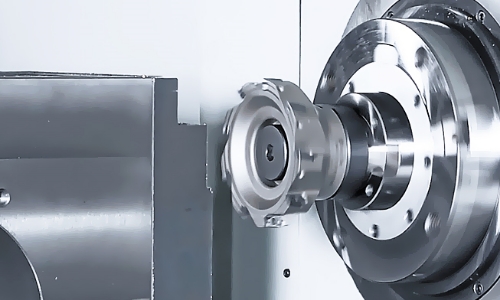

5 Axis Machining

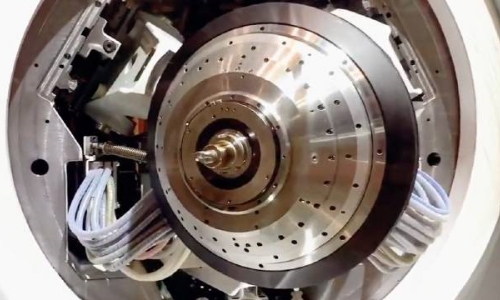

5-axis machining technology is an advanced machining technology. It uses A CNC machine tool with 5 or more controllable axes, which can simultaneously control the position and movement of the workpiece on 3 direct coordinate axes (X, Y and Z axes) and 2 or more rotating axes (A, B, C axes), and realize the complex physical machining of the workpiece.

The main advantages of 5-axis machining technology are:

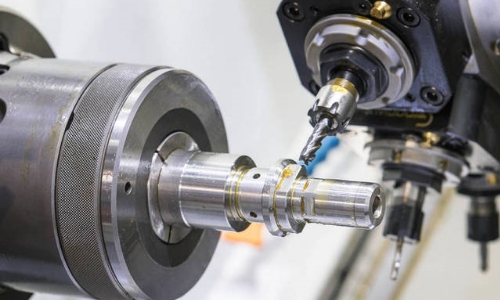

1. High efficiency: multiple processes can be completed at one time, reducing processing time and setting time, improving production efficiency.

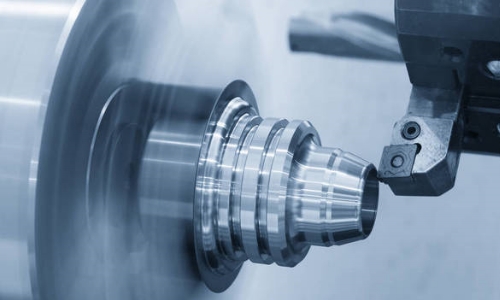

2. Accuracy: Through the cooperative control of 5 or more axes, complex surfaces and shapes can be precisely machined to achieve high precision machining.

3 General: can process a variety of materials of the workpiece, widely used in aviation, aerospace, energy, mold and other industries.

4. Labor saving: Due to the use of automatic processing, reduce manual operation, with high repeatability, reduce the probability of human error.

5. Good surface quality :5 axis linkage can maintain the ideal cutting conditions, reduce the change of machining section, obtain high quality surface effect.

Compared with the conventional 3-axis machining center, 5-axis machining technology has higher flexibility and stronger applicability, can process more complex parts, achieve high difficulty, high precision machining, to meet the requirements of modern manufacturing industry. It is a promising advanced technology in machining field.

Findtop has outstanding advantages in 5 axis processing technology

We are working with the best suppliers of advanced 5-axis machining technology to provide quality, cost effective custom machined parts from Asia using our own developed technology. The whole purchasing process is highly transparent, and you can keep up-to-date order information through our order tracking system.