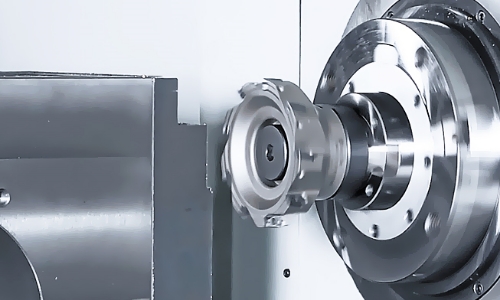

Gear Forming

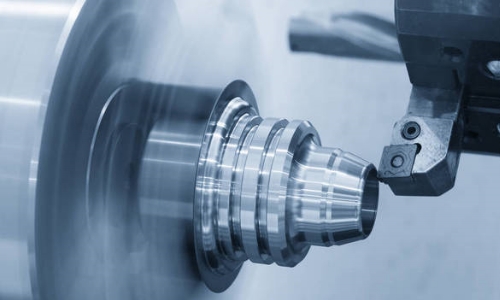

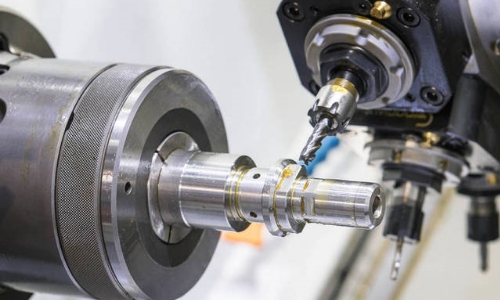

Gear cutting forming is a method of shaping gears by cutting. In this method, the tooth shape of the gear is cut by a tool matching the tooth shape. In the process of gear cutting forming, the cutting tool has the same shape as the gear tooth spacing space. This can be done by milling and broaching.

The main advantages of gear forming are:

1. High production efficiency. Gear molding adopts mass standardized production, continuous process, short production cycle and large capacity, which can realize efficient mass production of gear.

2. Stable and reliable quality. The gear forming process is mature, and the stability and reliability of the product quality can be guaranteed through the process control, which can meet the use requirements of most gears.

3. High dimensional accuracy. With the development of machining technology, gear forming can achieve higher dimensional accuracy, usually can reach 6-7 level, to meet the accuracy requirements of most standard gears.

4. Good surface quality. Good surface quality can be obtained by finishing gear forming. The surface roughness can reach Ra0.2um and improve the quality of tooth surface.

5. Lower cost. Gear forming adopts mass production, the process is more mature, can achieve higher production capacity and output, is conducive to reducing the production cost of unit product.

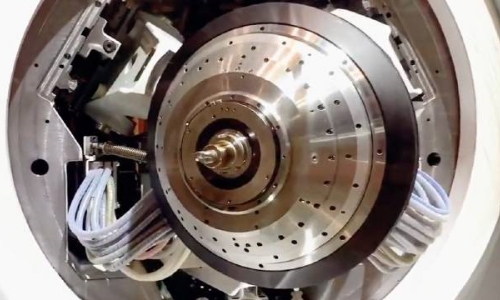

Findtop's strength in gear forming

We are working closely with top suppliers in the field of the latest gear forming technology, using proprietary intellectual property technology, to provide high quality, low cost custom machined gears from Asia. The entire ordering process is highly transparent, and you can get the latest progress of your order in real time through our order monitoring system.