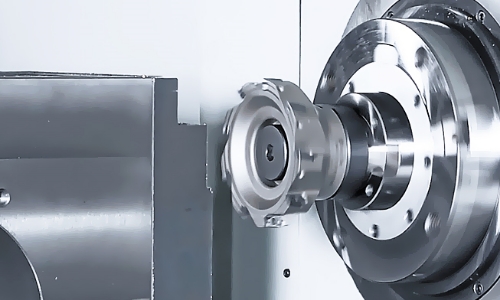

Turning

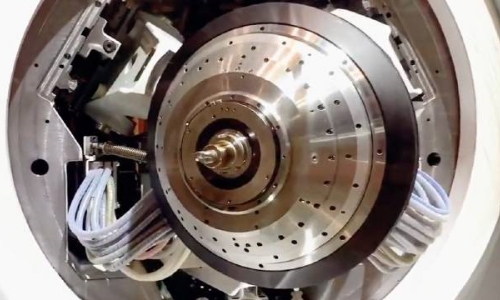

Turning is a common machining method, which uses lathes and turning tools for cylindrical machining of metal parts. Turning is an important means to realize accurate machining of cylinder and other axisymmetric parts, which is widely used in machinery manufacturing industry.

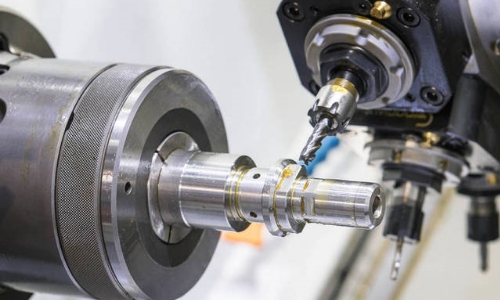

The main process of turning processing is: select the turning tool, clamp the workpiece, start the lathe spindle rotation, the turning tool moves along the axis of the workpiece, remove the residual material on the surface of the workpiece, and get the required size and surface quality. Among them, the choice of turning tool and the determination of cutting parameters are the key to obtain the ideal machining quality.

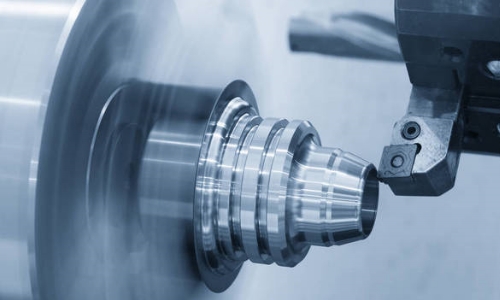

The main advantages of turning processing are:

1. High dimensional accuracy: turning can achieve high dimensional accuracy, especially suitable for machining high-precision shaft parts.

2. Good surface quality: good surface finish and high precision can be obtained by turning processing.

3. High cutting efficiency: fast cutting speed, high horsepower utilization rate, high production efficiency.

4. Good mechanical properties: high hardness of turning surface, good fatigue strength, to meet the requirements of mechanical strength.

5. Good product appearance: the turning surface has a high finish, which meets the appearance requirements of high-quality products.

Findtop turning strength

We are working with top suppliers in the field of turning technology to provide high quality, low cost custom machinated parts from Asia using proprietary intellectual property technology. The entire ordering process is highly transparent, and you can follow the latest progress of your order in real time through our order monitoring system.