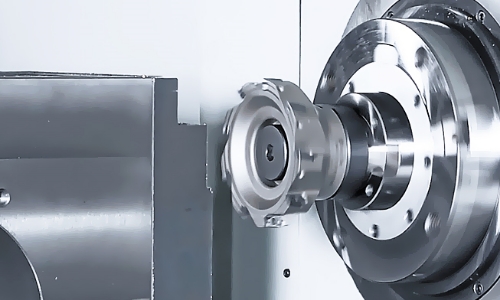

Swiss Machining

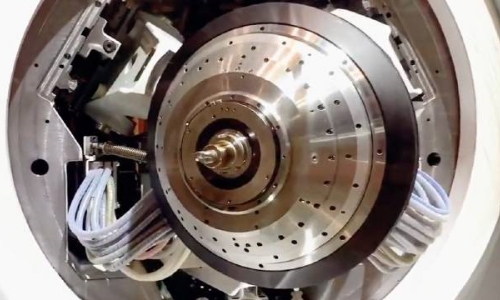

Swiss lathes are specialized lathes that use collets and guide bushings to provide additional support for the workpiece, providing higher rigidity and better machining accuracy than ordinary lathes.

The main advantages of the Swiss lathe are:

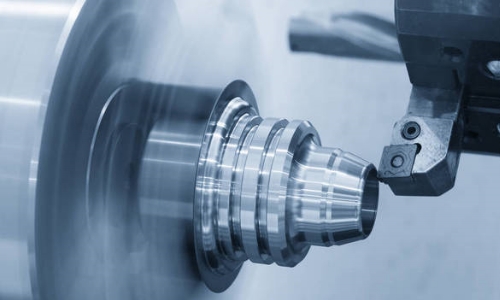

1. Use guide bushing to provide additional support for the workpiece. The guide bushing tightly surrounds the workpiece, providing it with rigid support, improv machining accuracy and surface quality.

2. High rigidity. Guide bushing provides support for exposed parts of the workpiece during turning, increasing the overall rigidity of the lathe and making it more suitable for precision machining.

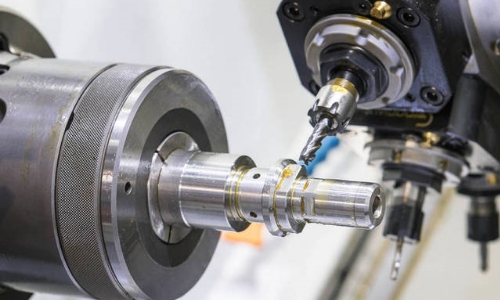

3. High machining accuracy. Due to the support of the guide bushing, the turning process can be carried out closer to both ends of the workpiece, effectively reducing machining errors and improving dimensional accuracy.

4 Suitable for small diameter and high aspect to diameter ratio of the workpiece processing. Guide bushing can effectively support small diameter and easy to zigzag deformation of long workpiece, to meet its processing requirements.

5. Reduce tool vibration. The guide bushing supports the workpiece and also plays the role of supporting the cutting tool, effectively reducing tool vibration and improving its dynamic rigidity.

Findtop's strength in Swiss machining

We are working with top Swiss suppliers in the field of precision machining technology, using proprietary intellectual property technology, to provide high quality, low cost custom machining parts from Asia. The entire ordering process is highly transparent, and you can follow the latest progress of your order in real time through our order monitoring system.