Boring & Milling Machining

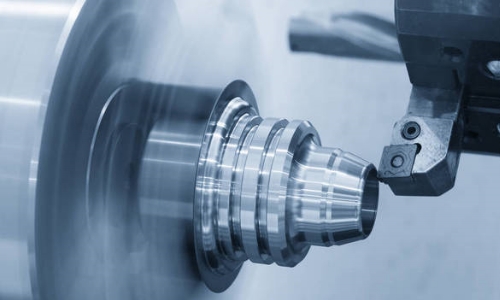

Boring and milling machining is a common mechanical machining method, which uses the boring and milling tool on the milling machine to process. Compared with a single milling process or drilling process, boring and milling process can be completed at the same time, such as drilling, boring and face milling, with higher production efficiency.

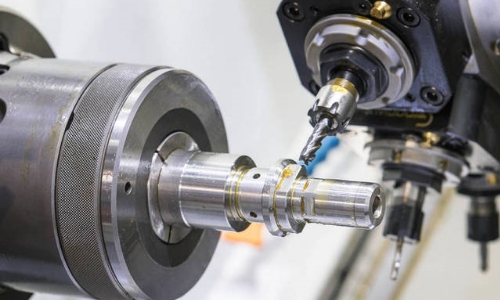

The main process of boring and milling processing is: select the appropriate tool, determine the processing sequence and tool stroke, clamping processing workpiece, start the milling machine spindle, so that the tool speed meets the requirements, feed the tool for cutting, to achieve the required hole processing, slot processing or surface processing of the workpiece. In the machining process, by adjusting the feed speed and spindle speed of the milling machine, the ideal cutting parameters can be obtained to ensure the machining quality.

The main advantages of boring and milling are:

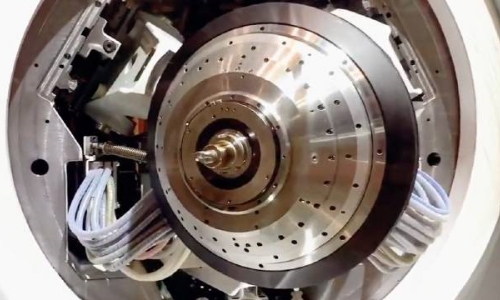

1. High efficiency: drilling, boring and milling can be completed at the same time, improve production efficiency.

2. Accuracy: The milling machine is used for processing, which can achieve high precision machining and high precision hole position.

3. Labor saving: Due to the use of mechanical automatic processing, reduce manual operation, reduce labor intensity.

4. Good working environment: in the closed milling machine processing, reduce noise and chip splash, to ensure the operator working environment.

5. High production capacity: can continuously produce large quantities of complex shapes of the workpiece, to meet the needs of mass production.

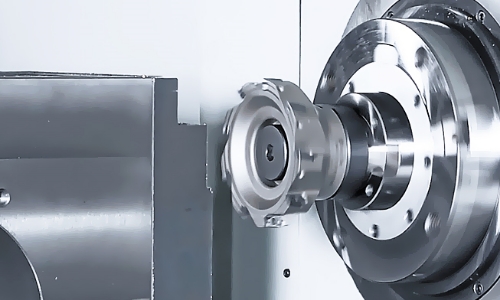

Findtop's strength in boring and milling processing

Findtop is partnering with leading suppliers of boring and milling technology to provide high-quality, customised machining parts at low prices from Asia using homegrown technology. The whole procurement process is highly transparent, and you can get the latest order status at any time through our order monitoring system.