Molding services

- Complete the quotation within 24 hours

- Delivery within 30 days

- Part consistency less than +/- 0.1mm

All uploads are secure and confidential

findtop's molding services

Findtop offers highly customized precision molding, on-demand molding and mass production molding services. Our advantage lies in excellent cost control, abundant production resources, faster delivery guarantee. From quotation to production and delivery, we provide a customized professional service team for each project, using technology to support production planning and execution.

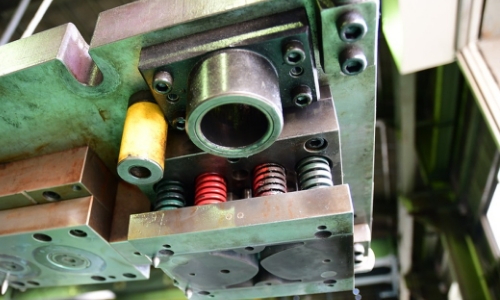

molding capabilities

Quality Certification

YY/T0287,YY/T0288,ISO 13485,ISO 9001,AS 9100,ISO 16949

Clean Room

ISO Class 8, ISO Class 7

Wide Range of Materials

PEEK, PEI (Ultem), PPSU, polycarbonate (PC), liquid silicone rubber (LSR), Ultem, TPEs, Radel, PSU, Delrin, Lexan, Pebax, ABS and

other hundreds of plastics, metal and elastomer materials

Machinable Size

From micro to 2400 square cm (based on the processing size of our standard mold), we can also provide manufacturing services for

larger products according to your requirements.

Cavity Tolerance

+/-0.01 mm when processing molds, increase of +/-0.05 mm per centimeter when calculating shrinkage

Consistency of Parts

Less than +/-0.1 mm

Tolerance of Key Features

Findtop can achieve higher tolerance requirements for some features

Mold Type

Customers can choose the most suitable mold core material based on the estimated sales of the part

Optimize the Supply Chain

Save resources, reduce manufacturing costs

Machine Equipment Resources

500+ different tonnage single-color, two-color, three-color injection molding machines

*The table above introduces general molding capabilities

Molding finishes

Standard Finish

Moldmaker’s choice of finish. Typically SPI B-3 to D-3 depending on geometry and drafts. Interior, non-cosmetic faces, are typically

as-machined.

SPI Finishes

Range of finishes from Grade 3 diamond / high polish to 320 stone low polish. Finishes include: SPI A-1, SPI A-2, SPI A-3, SPI B-1,

SPI B-2, SPI B-3, SPI C-1, SPI C-2, SPI C-3, SPI D-1, SPI D-2, and SPI D-3

MoldTech Finishes (Mold Texturing)

Range of finishes including matte, swirls, lines, and patterns. Our most common texture finishes include: MoldTech MT11010, MoldTech

MT11020, and MoldTech MT11030. Other textured finishes can be added on request.

As Molded

No secondary polishing or grinding. Part will show tooling marks.

Threaded Inserts

We can install most commonly used standard inserts in UNF and metric sizes.

Pad Printing

Transfer a 2D image onto a 3D part. All images are subject to review.

Laser Engraving

Engrave part numbers, logos, and more onto your parts.

Assembly

Findtop can assemble and label molded parts. Discuss your needs with your salesperson.

*Zinc plating, which is also known as galvanization, is applied to prevent the surface from oxidizing or corroding.

molding application

Large Mold

For mass production of identical parts, molding is the ideal choice, achieving high yields and repeatable precision with high tolerances.

Complex but low cost parts

Once the mold is finished, the mold can be quickly mass-produced at a lower unit price.

End-use Parts

Molding is ideal for end-use production, offering a wide range of material and surface treatment options from hard to soft plastics with high material stability.

why choose findtop for cnc machining?

Multiple Choice

A wide range of combinations of materials, tolerances, surface treatments, and markings.

On Demand Manufacturing

Place orders directly with our team, with the help of our internal engineers and flexible delivery times.

Real Time Orders

Stay up-to-date with the latest orders in real-time through our order management system.