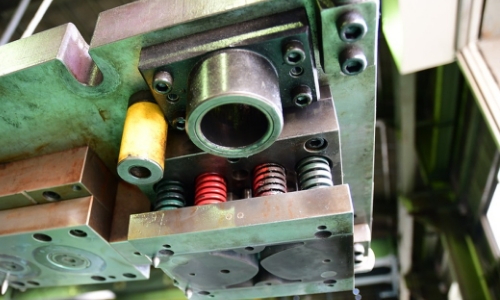

Rubber forming

Rubber molding is a method to make rubber materials reversible deformation under the action of heating and high pressure to obtain a variety of rubber products. It belongs to rubber processing technology, has the advantages of high production efficiency, excellent product performance, widely used in rubber industry.

The main advantages of rubber molding are:

1. High production efficiency. Automatic continuous production, short production cycle, strong production capacity.

2. Excellent product performance. High density, good mechanical strength, durability and resilience.

3. Wide range of applications. Can produce a variety of rubber products, a wide range of applications.

4. The equipment and mold are complicated. Requires heating device, injection system and control device, the equipment is more complex.

5. High energy consumption. The rubber needs to be heated to high temperature melting state first, and then forming, which has high energy consumption.

Findtop's strength in rubber molding

We are working closely with top suppliers in the field of rubber molding technology, using proprietary intellectual property technology, to provide high quality, low cost custom machinated parts from Asia. The entire ordering process is highly transparent, and you can get the latest progress of your order in real time through our order monitoring system.