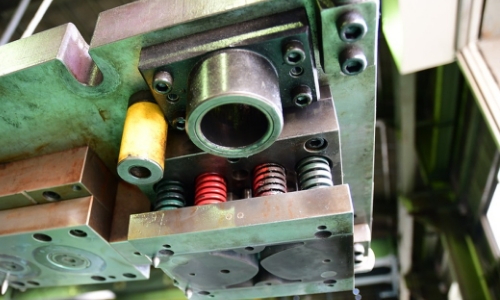

Multi-shot injection molding

On the basis of conventional injection molding, multiple injection molding machines are used to inject molten plastic into a mold cavity at the same time in order to shorten the molding cycle and increase the production capacity. Compared with single injection, multi-injection has the advantages of high production capacity, saving time and energy, and has broad application prospects in mass production of plastic products.

The main advantages of multi-injection molding are:

1. High production efficiency. Multiple injection molding machines at the same time into a mold injection, can greatly improve the production efficiency of the product, the production cycle is shortened by more than 50%.

2. Increased production capacity. Compared with single injection, multi-injection can significantly increase production capacity and improve equipment utilization.

3. Save time and energy. Shorten the production cycle, can save time and energy consumption, with higher economic benefits.

4. High accuracy. With precision mold and synchronous control system, highly consistent products can be obtained with high accuracy.

5. Stable quality. Multipoint injection can produce uniform arrival effect, which is conducive to the stability of product size and performance.

Findtop's strength in multi - shot injection molding

We are working closely with top suppliers in the field of multi-injection molding technology, using proprietary intellectual property technology, to provide high quality, low cost custom machined parts from Asia. The entire ordering process is highly transparent, and you can get the latest progress of your order in real time through our order monitoring system.