Rotary forming

Rotary forming is a method of using the rotating core of the mold cavity. After the injection of the plastic melt, the melt is evenly distributed on its surface through the rotating action of the rotating core, and the melt is finally solidified and formed with the rotation. It can produce thin wall hollow rotating symmetrical plastic parts, has the characteristics of high production efficiency, saving material and energy.

The main advantages of rotary forming are:

1. High production efficiency. Continuous automatic production, short production cycle.

2. High plastic utilization rate. 70-95% plastic can be used, with less material loss.

3. Low energy consumption. No additional heating and molding, direct use of injection molding machine to provide heat energy, low energy consumption.

4. Freedom of styling. Can produce a variety of hollow rotary symmetrical shape plastic parts.

5. Uniform wall thickness of the product. The melt is evenly distributed and thinned on the surface by rotating motion, and the product wall thickness is uniform.

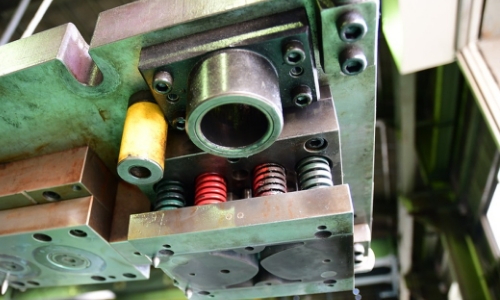

Findtop's strength in rotary molding

We are working closely with top suppliers in the field of rotary molding technology to provide high quality, low cost custom machinated parts from Asia using proprietary intellectual property technology. The entire ordering process is highly transparent, and you can get the latest progress of your order in real time through our order monitoring system.