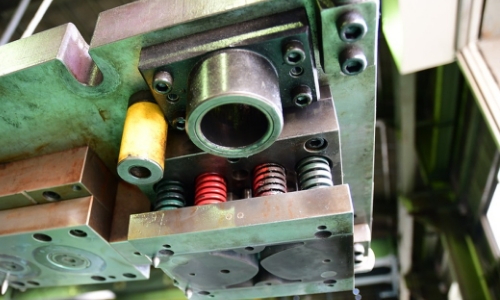

Injection molding

Injection molding is a process in which molten plastic polymer is injected into a mold cavity and then solidified into a plastic part. It uses high pressure plastic powder or particles with strong plasticity into the mold, after cooling and solidification to produce plastic products of various shapes.

The main advantages of injection molding are:

1. High production efficiency. Using automatic device, short cycle, large capacity, can achieve mass production.

2. High accuracy. The mold adopts precision machining, the product precision is high, the size error is usually within 0.2%.

3. Good surface quality. Product surface smooth, no porosity, good surface quality, high appearance quality.

4. High mechanical performance. Because injection parts are formed under the condition of rapid cooling, they have high density, high mechanical strength and strong impact resistance.

5. High plastic utilization rate. The artificial loss rate of injection molding is low, and the utilization rate of plastic can reach more than 95%.

Findtop's strength in injection molding

We are working closely with top suppliers in the field of injection molding technology, using proprietary intellectual property technology, to provide high quality, low cost custom machined parts from Asia. The entire ordering process is highly transparent, and you can get the latest progress of your order in real time through our order monitoring system.