Blow Molding

Blow molding is the method of heating and softening the prefabricated plastic tubular billet or ball with high temperature and high pressure air, and then injecting it into the mold, and blowing the softened plastic into hollow plastic products with air. It uses hot air rather than liquid as the blowing medium, with high production efficiency, low energy consumption, less pollution and other advantages.

The main advantages of blow molding are:

1. High production efficiency. Can realize automatic continuous production, short cycle, large output.

2. Save resources. Only less plastic raw materials, the use of air as a blowing medium, eliminating the occupation of liquid media in other blowing process.

3. Low energy consumption. Only lower heating temperature and pressure, lower energy consumption.

4. Good environmental protection. The use of air as a blow molding medium avoids the pollution of liquid media in other processes.

5. High plastic utilization rate. Up to 95% of plastic can be used.

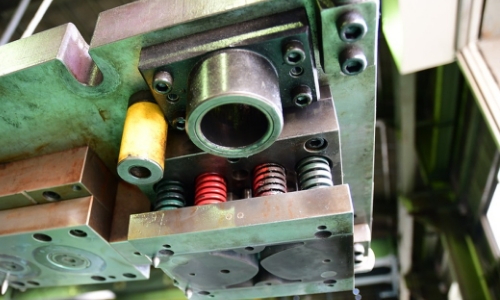

Findtop's advantage in blow molding

We are working closely with top suppliers in the field of blow molding technology to provide high quality, low cost custom machinated parts from Asia using proprietary intellectual property technology. The entire ordering process is highly transparent, and you can get the latest progress of your order in real time through our order monitoring system.